Best Finish for Live Edge Tables in Texas Climate

Texas is hard on wood. We have humid springs, scorching summers, and AC units running full blast. This constant swing between outdoor humidity and indoor dry air is a torture test for furniture finishes.

The Problem with "Plastic" Finishes

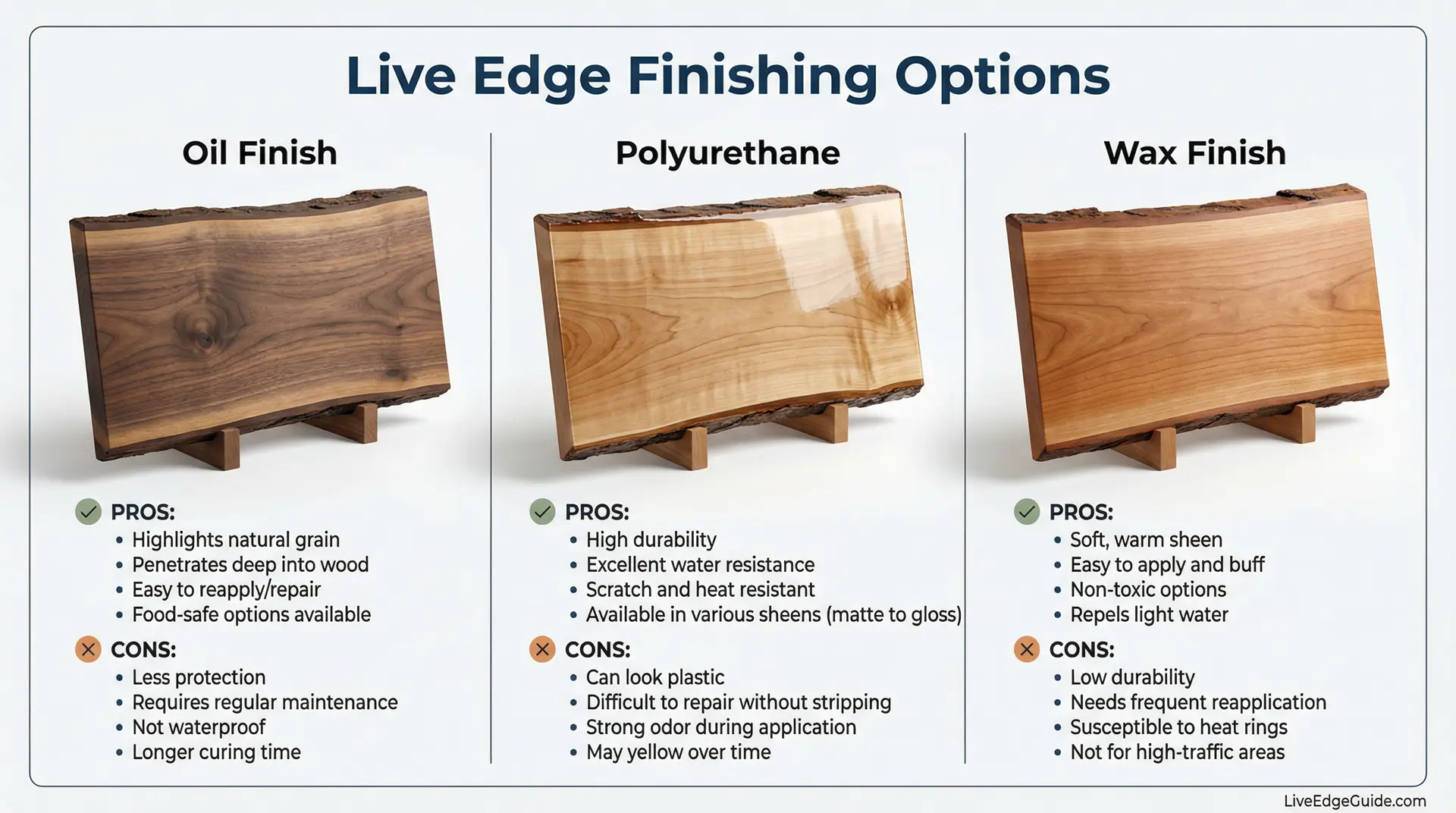

Thick, glass-like epoxy or cheap polyurethane coatings form a rigid plastic shell on top of the wood.

- The Texas Issue: When the wood tries to expand in humidity, the rigid plastic shell doesn't stretch. It cracks. Once moisture gets under that crack, it turns milky white and begins to peel.

The Solution: Flexible, Penetrating Finishes

We recommend finishes that move with the wood, not against it.

1. Hardwax Oil (Rubio Monocoat)

This is our #1 choice for Texas homes.

- How it works: It bonds molecularly with the wood fibers within the slab, rather than sitting on top.

- Flexibility: It is flexible. As the wood expands/contracts, the finish doesn't crack.

- Repairability: If you get a scratch, you just buff a little oil into that spot. No sanding the whole table.

- Heat: It handles Texas heat well without softening like some cheap varnishes.

2. Catalyzed Conversion Varnish (Professional Only)

For commercial spaces (restaurants, bars), hardwax oil might require too much maintenance.

- The Upgrade: We use a catalyzed varnish that has "elasticity" additives. It provides the spill protection of a poly but has enough give to handle slab movement without cracking.

Ongoing Care in Texas

- Keep it away from the vent: Don't place your table directly under an AC vent. The cold, dry air blasting on one spot will warp it.

- Humidity Control: If you can, keep your home between 40-50% humidity.

Expert Finishing Services

Have a slab that needs a Texas-proof finish? We offer flattening and finishing services.

Contact Workshop